おやつができるまで

- それでは今回は、ササミとチーズが二層になっているPetioの人気のおやつ「おなかにうれしい ササミとチーズ」のつくりかたを見ていこう!

おなかにうれしい ササミとチーズ

STEP1 材料の下準備

まずはおやつのササミの層の材料を合わせていくよ。生のササミをミンチにするよ。

全卵や小麦粉などほかの原材料と一緒に「サイレントカッター」で均一にこね合わせると……

しっとりしたタネができあがるよ。鶏ササミは人の食品用のものを使っているから、新鮮でおいしそう!チーズの層も同じようにタネを練り合わせて用意したら下準備はOK!

STEP2 二層を合わせて形をつくる

「ホッパー」と呼ばれる容器にササミの層とチーズの層をセット!

ポンプで成型する機械に流し込み、幅5cmほどの帯状に押し出すよ。上がチーズ、下がササミの層になっているんだ。それぞれの層の厚みが均一になるように、できあがりをつぶさにチェックしながらスタッフが成型機の設定を微調整しているよ。熟練の腕の見せどころだね!

STEP3 高温で蒸す

成型された生地はそのままスチーマーで蒸されるよ。おやつの種類によって、蒸す時間や温度は変わるけど、「おなかにうれしい ササミとチーズ」の場合は約5分半、100℃近い温度で蒸して調理しているんだ。

スチーマーから出てきたばかりの「おなかにうれしい ササミとチーズ」。湯気が立っておいしそうな香りがほわわ~んと漂ってきた……!できたてをちょっとつまんでみたら、もちもちしていて、すごくやわらかかったよ。このままあげてもワンちゃんに喜ばれそう~!

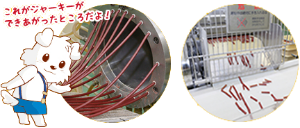

- 一般的なジャーキーの場合は加熱調理するよ!

- 細長いスティック状のジャーキーの場合は、フードと同じように「エクストルーダー」という機械で加熱調理するよ。 エクストルーダーの穴から押し出されたジャーキーは、あら熱を取ったらすぐにカッターで製品サイズに切りそろえられるんだ。

STEP4 じっくり乾燥する

1メートルほどの長さに切りそろえた生地を箱に詰めて、乾燥機に運ぶよ。

「おなかにうれしい ササミとチーズ」は6時間かけて、じっくり乾燥する必要があるんだ。

高温だと表面だけ乾いて、中まで均一に乾きにくいから、途中で温度を変えて乾き方を調節しているんだよ。やわらか食感のおやつをつくるためには、大切なひと手間なんだね。

- 検査室で品質チェック!

- ペットフードと同じく、おやつも検査室で毎日品質チェックを受けているよ。ジャーキーは1時間に1回、スチーマーを使うおやつは、乾燥したブロックごとに確認。 水分値や水分活性値などが一定であることを確認してから、袋詰めのGOサインが出るんだよ。

STEP5 製品サイズに切りそろえる

乾燥がおわった「おなかにうれしい ササミとチーズ」をカッターで製品サイズに切りそろえるよ。

できあがったおやつはサイズが均一かどうか、熟練のスタッフがしっかりチェックしているんだ。

- 今回は短いスティック状にカットしたけど、カッターの刃を変えることで、製品に合わせて波型やキューブ型に切りそろえることもできるんだよ。

STEP6 おやつのできあがり!

こうしてようやく袋詰めの作業に入るんだ。まずはパッケージ専用の機械で、製品ごとに設定された内容量に振り分けられて、金属探知機で金属片が混ざっていないのを確認したあと、1分間に約40個のペースで自動包装。その後、パッケージに消費期限などを印字したり、内容量を最終確認して、すべてOKだったら晴れて安全でおいしいおやつとして出荷されるんだ。心のこもったおやつをぜひワンコさんたちに食べてもらいたいな!