Until pet food is made

- What we are making this time is "Limonite Lab for indoor dogs". Natural mineral <Limonite> that will cut about 80% of the stinky odor is included!

Limonite lab for indoor dogs

Preparation of STEP 1 material

Well, let 's get rid of pet food making at once! First of all, I will begin preparing materials. Put all ingredients of food, such as meat, in a machine called "silent cutter", evenly mixed. ...... It looks like he is kneading a hamburger steak!

The factory staff checks it like a recipe book for cooking. The Himeji factory is making several types of pet foods, but each one has the optimal nutritional balance that matches the characteristics of the food, so the proportions of raw materials and formulations are different.

STEP 2 Bake while kneading with a cooker

The "pine" of the completed pet food is carried to the heating cooking line with the lift. You can just stir in a container like a bowl of dishes called "hopper" on a belt conveyor.

Then in a heating cooker like the "Extruder" like an oven, it heats up at a high temperature of 150 ℃ at once! Two screw shafts are moving in the extruder, and it is kneading the hood while heating. To put it simply, is it close to the image that kneads the cookie dough and bakes it in the oven?

The hood is made hot and soft, so it is extruded like a tokoroten from the four holes and it can be cut into granules with a rotating cutter.

STEP 3 Take the heat and let it cool down

The freshly prepared hood is sent to a machine like a refrigerator called "spiral freezer" by being sent with powerful wind and flying in the tube to take heat.

The upper right of the photo is the control panel of the spiral freezer. They change the temperature setting etc. depending on climate. Inside of this, a hood riding on a belt conveyor will flow and it will be cooled for about 3 minutes.

Well, finally, food has come out of the spiral freezer. Can I eat something? !

STEP 4 Quality check in examination room

This is an inspection room attached to the factory! The finished food regularly checks the quality every day. Fine the food with a food processor and measure the moisture value etc. The result of the inspection is to be informed to each staff who is in the production line immediately by e-mail. Based on the result, we adjust the temperature setting etc. of heating cooking, if necessary, and keep constant quality.

STEP 5 Inspection, inspection, inspection !!!

Finally bagging! Approximately 60 bags per minute can be packed in a package that can be packaged, and the hood is first delivered to the content determined for each product.

Then inspect with a metal detector. In the unlikely event that metal pieces get mixed in, it will be discarded to the left red cylinder and discarded. If there is no problem, you can pack it in a sachet together with an oxygen scavenger to keep the freshness of the hood.

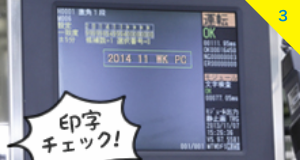

On the sachet packing the food, the expiration date and the product lot number are printed. Machine checks for lack of characters etc in printing.

Check the contents of the bag with X-rays to see if there is an oxygen scavenger or no foreign matter in it.

Finally we check whether the content content determined for each product is met and the inspection is over! In order to create a product that can be safe, you need a thorough examination so far.

STEP 6 Completion of pet food!

The inspected pouch's hood was packed carefully in the package (outer bag) with the staff's hands and sealed, and at last the "Limonite Lab for all dog breeds" was completed! Once you can ship it in cardboard soon it will be shipped in a shop such as a pet shop.